Separator CAD-4

Separator CAD-5

Separator CAD-7

Separator CAD-10

Separator CAD-10-01

Separator CAD-15

Separator CAD-20

Separator CAD-30

Separator CAD-40

Separator CAD-50

Separator CAD-100

Separator CAD-150

Grain loaders

|

|

|

Research on concentration of iron ore

|

|

SPC "Aeromeh" Ltd. carried out semi-industrial trials on concentration of iron ores with the help of air separation on CAD machine.

Trials were carried out for material of 4 samples of iron ores that have been taken from different opencast mines. When selecting samples were guided by the value of the total iron content in the ore.

Brief characteristics of samples are shown in the Table 1.

Table 1. Characteristics of the studied iron ores

| Number of the opencast mine |

Content Fetotal, % |

Humidity, % |

| 1 |

51,73 |

8,0 |

| 2 |

56,09 |

2,5 |

| 3 |

55,69 |

11,3 |

| 4 |

58,87 |

7,5 |

Samples 1, 3 and 4 were previously dried to humidity 2,0 mas. %.

Before carrying out trials on concentration of ores all 4 samples were crushed in two phases. As a result from each sample were got 2 samples of the ore material with particle size 5-0 and 1-0 mm. Trials on concentration of ores with the help of air classification were carried out for both granulometric fractions of all 4 samples.

Trials on air separation were carried out in two phases.

During the first phase were determined possible qualitative indexes of separating trial samples with the help of air separation.

Results of trials on concentration of ore material with particle size 5-0 mm are shown in the Table 2.

Table 2. Results of air separation of iron ore samples with particle size 5-0 mm

| Number of the opencast mine |

Content Fetotal in the concentrate, % |

Output of the concentrate, % |

| 1 |

56,38 |

53,0 |

| 2 |

60,54 |

57,7 |

| 3 |

60,34 |

37,2 |

| 4 |

61,12 |

53,7 |

Results of trials on concentration of ore material with particle size 1-0 mm are shown in the Table 3.

Table 3. Results of air separation of iron ore samples with particle size 1-0 mm

| Number of the opencast mine |

Content Fetotal in the concentrate, % |

Output of the concentrate, % |

| 1 |

58,63 |

29,2 |

| 2 |

62,72 |

34,8 |

| 3 |

61,70 |

29,2 |

| 4 |

63,12 |

29,7 |

CONCLUSION:

1. There were carried out semi-industrial trials on concentration of 4 samples of iron ores with the help of air separation method. Size of particles in the initial material was 5-0 and 1-0 mm. Humidity of samples was about 2 mas. %. For concentration was used serial air separator CAD-4.

2. There were confirmed results of preliminary trails on possibility of using air separation for concentration of iron ores.

3. Concentrates with content of iron more than 60% were obtained from ores of 2, 3, 4 opencast mines.

4. From ore of 1 opencast mine were not obtained concentrates of the required quality in none of the samples due to predominance of lowiron gethylic component in the ore.

5. From material with particle size 5-0 mm were obtained concentrates with content of iron 60,34-61,12% with output 37,2-53,7%.

6. From material with particle size 1-0 mm were obtained concentrates with content of iron 61,70-63,12% with output 29,2-34,8%.

7. Received results allow to recommend air separator SPC “Aeromeh” Ltd. as a unit for concentration of iron ores.

|

|

|

| News

|

STRENGTH AND ENERGY IN EVERY GRAIN

20 april 2020

|

|

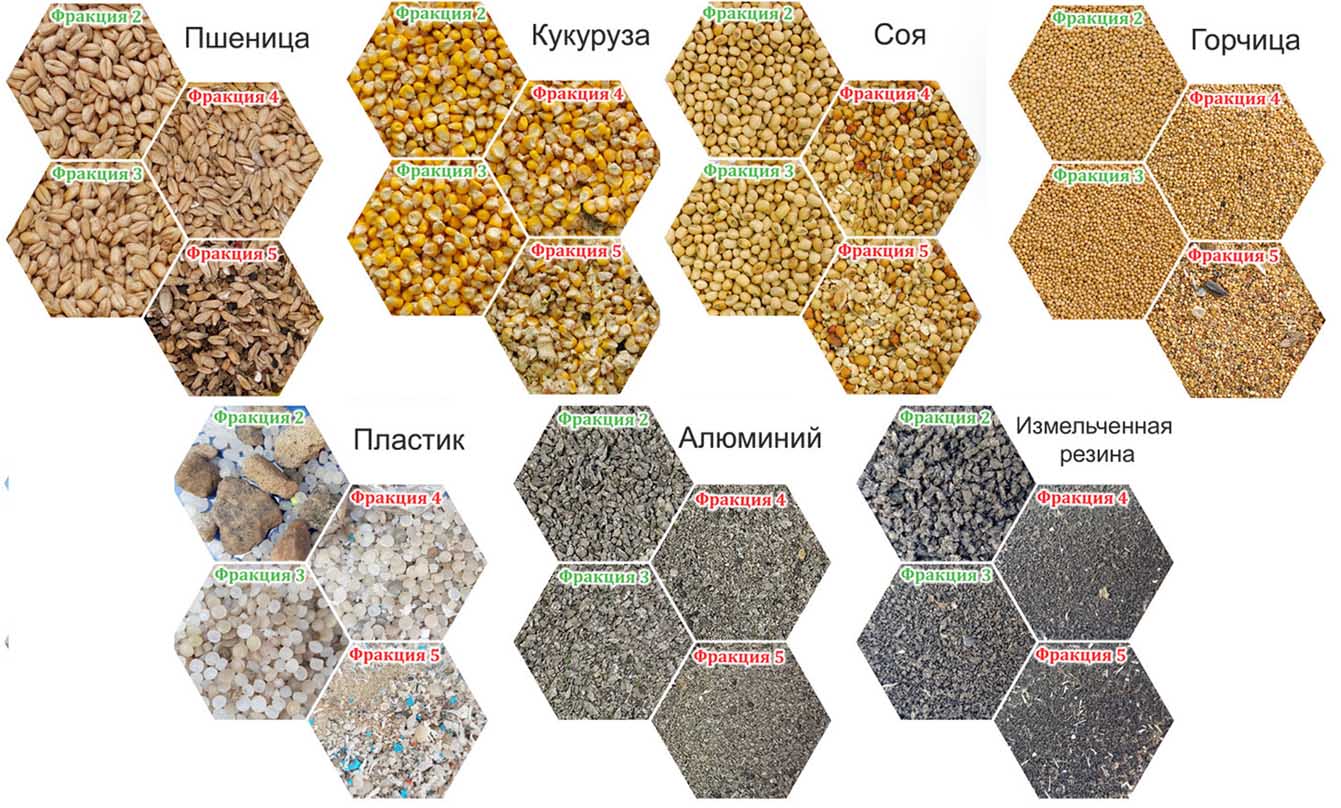

During the harvesting and preparation of grain crops for storage, it is very important to accurately complete all stages of the post-harvest process. One of the most significant steps is grain cleaning. It makes it possible to save the crop from dust and impurities, weeds, pests, dry mass, separate the seeds, and also qualitatively prepare the grain for further storage and processing. Universal grain cleaning equipment CAD separators has a high capacity, processing almost all types and varieties of crops, legumes, oilseeds, industrial, small-seed herbs and vegetables. The grain separator can be used independently or in combination with other units, performing the complete chain of processing crops. AEROMEH company offers grain cleaning machines for various tasks. From us you can buy small separators CAD-4 and CAD-5 for small farms, as well as grain separators CAD-100 and CAD-150 - more productive and always efficient. Grain cleaning equipment of AEROMEH production consists of several components. Grain enters the hopper feeder of the CAD separator. With the help of the vibrating tray, the grain is evenly distributed in the separation chamber over its entire width. Air flow generator of the CAD grain separator processes each element of the separated stream with the powerful flows. During this process, the heap is cleaned of dust, light impurities, crushed grain, weed seeds and other mineral and green impurities. Separation or sorting of grain with the CAD separator is done into 5 fractions. After cleaning with the separator CAD, the best and cleanest grain goes to the 2nd and 3rd fractions. Small impurities, crushed seeds and waste of various origins go to the 4th and 5th fractions. In the calibration mode, the 2nd and 3rd fractions of CAD separators is proper seed material, which is obtained by selecting the grain by the specific weight. The equipment has durable body, and does not have replaceable elements and lubrication points, therefore it can work for many years without failures in operation. At the peak of the season, when the grain cleaning is carried out for many hours in a row, it is very important that the machines work clearly and smoothly, because every day of a downtime can bring losses to the agricultural economy. We offer reliable equipment that does not require expensive consumables or special care, it gives maximum efficiency without taking significant investments. AeroDynamic separator CAD is a modern and reliable grain cleaning equipment. Innovative solutions used in the CAD separator allow to solve a lot of problems in the field of grain cleaning. In addition, CAD is a technology for producing high-yielding seeds. Time tested.

phones.

Administrator www.aeromeh.com

See all news

|

Marry Cristmass

20 december 2019

|

|

"Aeromeh" team wishes everyone a Happy New Year and Merry Christmas. Let your wishes come true, let your ideas successfully come true, let your aspirations and dreams lead you to new heights of happiness. Be loved in the new year and be healthy, live well and remember: we value each of you.

Read more about our location at the exhibition on our phones.

Administrator www.aeromeh.com

See all news

|

AEROMEH invites to Kiev for the international exhibition AGRO-2019

1 june 2018

|

|

From 4 to 7 June 2019 in Kiev will be held the largest international agro-industrial exhibition in Ukraine and Eastern Europe, "AGRO-2019".

AEROMECH invites you to visit our stand, which will be located near pavilion 9, place В06.

You will be able to see our equipment in operation, as well as get acquainted with the new products. You also have the opportunity to bring grain samples with you to test our grain cleaning machines at work.

We will be glad to welcome you at our stand!

Read more about our location at the exhibition on our phones.

Administrator www.aeromeh.com

See all news

|

|

Separator CAD-4

Separator CAD-4 Separator CAD-5

Separator CAD-5 Separator CAD-7

Separator CAD-7 Separator CAD-10

Separator CAD-10 Separator CAD-10-01

Separator CAD-10-01 Separator CAD-15

Separator CAD-15 Separator CAD-20

Separator CAD-20 Separator CAD-30

Separator CAD-30 Separator CAD-40

Separator CAD-40 Separator CAD-50

Separator CAD-50 Separator CAD-100

Separator CAD-100 Separator CAD-150

Separator CAD-150 Grain loaders

Grain loaders